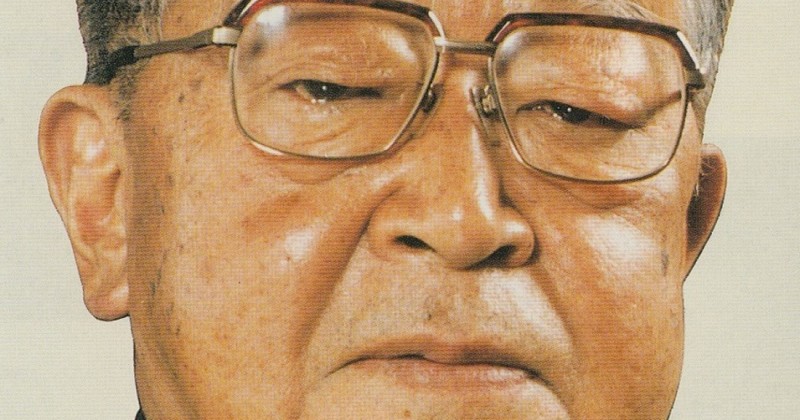

Kaoru Ishikawa: biography of this management science expert.

A summary of the life of Kaoru Ishikawa, a researcher specialized in quality control.

Kaoru Ishikawa was a great Japanese scientist, industrial chemist by profession and famous for his way of managing companies in the style of the Japanese culture.

His main contribution to the business world is related to quality control, an area in which he applied his cause-effect model, also called Ishikawa diagram, which aims to identify the problems that a company may encounter.

We will now take a look at the life of this researcher we will see the life of this researcher by means of a biography of Kaoru Ishikawa in which we will know his life trajectory and, above all, what are his main contributions to the business world and quality control.

Brief biography of Kaoru Ishikawa

Kaoru Ishikawa's personality could be defined as that of a hard-working person and, at the same time, very concerned about the quality of life of the workers. very hardworking and, at the same time, very concerned about the quality of life of the employees.. He believed that a company should not treat its workers "Western-style" if it wants to ensure that its services and products are always of the highest quality. It is necessary that workers feel motivated and at ease with what they do, in addition to feeling that they are an essential part of the process.

Early years

Kaoru Ishikawa (Ishikawa Kaoru in traditional Japanese order) was born on July 13, 1915 in Tokyo, Japan. He grew up in a family related to the industrial field and with good wealth. His father was an important industrialist, a fact that had a great influence on young Kaoru's professional future. Thanks to the good economic situation of his family Ishikawa was able to receive a very good education attending the best schools in Tokyo.

World War II

In 1939 he graduated in applied chemistry from the prestigious Imperial University of Tokyo, but it was not until 1960 that he could obtain his Ph.In 1939, he earned a degree in applied chemistry from the prestigious Tokyo Imperial University, although it was not until 1960 that he was able to obtain his doctorate from the same institution, presenting a doctoral thesis on the sampling of coal. At the beginning of World War II, between 1939 and 1941, Ishikawa helped his country by serving in the Japanese Navy. He would later work for the Nissan Liquid Fuel Company.

In 1945 he made his first major contribution to business management by introducing the fishbone diagram, which was to become his first major contribution to business management.which would become very popular with the passage of time. Although he had already tested it years earlier, working with engineers in a war context, it would not be until the end of the conflict that he would fully develop it. His main objective with this tool was to find solutions to a company's main problems by finding and understanding their causes.

Postwar

In 1945, the Second World War came to an end and the Land of the Rising Sun ended up losing. The country had put all its efforts into the manufacture of armaments during the conflict and, now that it had just lost, it was only a matter of time before it was punished for it. In fact, it was on the verge of being divided into several pieces, as did its ally Germany. Finally, the United States occupied the country to make sure that the Japanese military industry paid for what it had done.

The Japanese outlook is bleak. The empire is in a severe economic depression and is facing a terribly harsh post-war period.. However, the American invaders do not limit themselves to prevent the country from reactivating its imperialist pretensions, but also intend to help it recover economically and scientifically. It was not only military personnel who set foot on the archipelago, but also scientists from the United States who came to help the civilians rebuild their country.

Against this background, in 1947 Ishikawa accepts a position as a professor at the University of Tokyo.. In addition, he decided to join the Japan Union of Scientists and Engineers (JUSE), an organization that was conducting research on quality control and delimitation. It is thanks to the American scientific "invasion" that Ishikawa has the opportunity to meet two American theorists, William Deming and Joseph Duran. With them he would develop new management concepts that would be used in Japanese industry.

After the post-war period and the last years

In 1960, having already obtained his doctorate, Ishikawa began to teach engineering and received awards for his work, such as the Deming Prize and recognition from the American Society for Quality Control (ASQC). In the same year, Japan joined the International Organization for Standardization (ISO), which is responsible for setting quality standards for products and companies.. Ishikawa was a member of this organization until 1977 and became the chairman of its delegation in Japan.

He would later be appointed president of the Musashi Institute of Technology in Japan and would continue to provide solutions to improve the implementation of quality systems. With them he sought to streamline and improve processes within companies, and it would be at this time that he would develop his great theory of the quality system. Kaoru Ishikawa was always a hard worker, and the only thing that prevented him from continuing was a stroke. After several months, he died in his native Tokyo on April 16, 1989 at the age of 73..

His industrial philosophy

Kaoru Ishikawa's quality principles were strongly influenced by the culture of Japan, especially the philosophy of kanji learning.. Written Japanese is characterized by three writing systems; the hiragana and katakana syllabaries, in which each symbol represents one or two phonemes, and the kanji, a logographic system, i.e., in which each symbol represents ideas. These characters can mean different things in isolation or accompanied by other kanji.

The kanji system has its origins in China and has practically an infinite number of characters. In order to be able to read a Japanese newspaper without difficulty, it is necessary to have learned about 2000 basic kanji, knowing how to read them and write each of their strokes correctly and in the right order. As this system, which is made up of thousands of symbols, never stops being learned, Ishikawa considered that the difficulty of learning the kanji system is conducive to reinforcing the habits of precise work.

But his philosophy is not only linked to this characteristic aspect of Japanese culture. Ishikawa had a conception of the human being that was closely related to Jean-Jacques Rousseau's idea that man is good by nature, involving himself positively in that which is so characteristic of Japanese culture.He was positively involved in what affects and interests him. Ishikawa criticized the Western production model which, it seemed, completely ignored Rousseaunian thinking and treated the worker with little respect.

The Western model of production is based above all on the thinking of Frederick Winslow Taylor and Henry Ford. Their conception was related to the idea that man was evil by nature and they reduced the worker to a disposable object, a simple link in the chain that if it breaks can be replaced by another. In the assembly line he had to be squeezed to the maximum and every action he performed had to be controlled to the millimeter in order to economize the production process.

Ishikawa did not think like that at all. He considered the workers to be more than just cogs in the assembly line and that, in order to guarantee the quality of the product and that, to guarantee the quality of the product, the commitment of the workers had to be achieved by treating them as what they are, people. Only then will workers have an interest in improving product quality and increasing production. The moment the employee's rights are recognized, he/she will have a greater interest and commitment to the company.

To ensure the good quality of products in an organization, Ishikawa established a series of quality principles, Ishikawa established a series of quality principles, which were focused on increasing the control of the whole system.. If successfully implemented, the company will progressively improve and the customer will receive the best quality product. Among these principles are the following:

- Quality begins with education and ends with education.

- In order to achieve quality, you must first know what the customer wants.

- Quality control reaches its ideal state when inspection is no longer necessary.

- The causes of problems must be found and eliminated.

- All workers in all areas must be involved in the quality control process.

- Means should not be confused with objectives.

- Quality is a priority and profits must be considered in the long term.

- Business managers must accept that their subordinates present them with the facts.

- Problems can mostly be solved with analysis and problem-solving tools.

- Data without variability should be considered false.

Contributions to the world of organizations

Ishikawa's main written work is his book What is Total Quality Control: The Japanese Approach? (1986). This is a book in which he explains that quality control in Japanese society is characterized by the participation of all the components of the company. It is not only a matter of the top management and other top managers; the rest of the organizational structure, including the lowest part of the hierarchy, must also be involved in quality control for the product to be optimal.

In 1943, in the midst of World War II, Ishikawa presented the first diagram designed to help engineers in Japanese industry to find, document and select the causes that caused the quality of the same product to vary. help engineers in Japanese industry to find, document and select the causes that caused the quality of the same product to vary from one product to the next.. This is the moment when his well-known cause-effect diagram, later renamed Ishikawa diagram and extensively developed at the end of the conflict, was born.

Ishikawa Diagram

The Ishikawa diagram aims to present the possible causes of problems affecting quality in a company by trying to categorize them. It is also called a fishbone because it resembles one in its graphic representation.

First a horizontal line is drawn, which symbolizes the problem being analyzed, and then the members of the organization identify the causes of the problem, the members of the organization identify its causes and possible effects by brainstorming ideas.. In his book Ishikawa considers it the first tool to solve problems in the production chain.

Quality circles

Another of Kaoru Ishikawa's most important contributions are the quality circles, designed to manage organizations. They are elaborated in the form of working groups made up of personnel who perform similar activities within the organization and each is led by a supervisor.

All its members analyze the problems that arise within their circle, and contribute possible solutions. The main objective of this system is to identify the source of the problem affecting the company and eliminate it at its root.

In order to carry out this task, quality circles use Ishikawa's seven tools, which he himself explained in his book What is Total Quality Control: the Japanese approach?.

- Cause-Effect Diagram or Ishikawa Diagram

- Inspection templates

- Control charts to measure and control variations

- Stratified sampling or stratification analysis

- Histograms providing data on variations in a process

- Pareto diagrams

- Scatter diagrams

(Updated at Apr 14 / 2024)